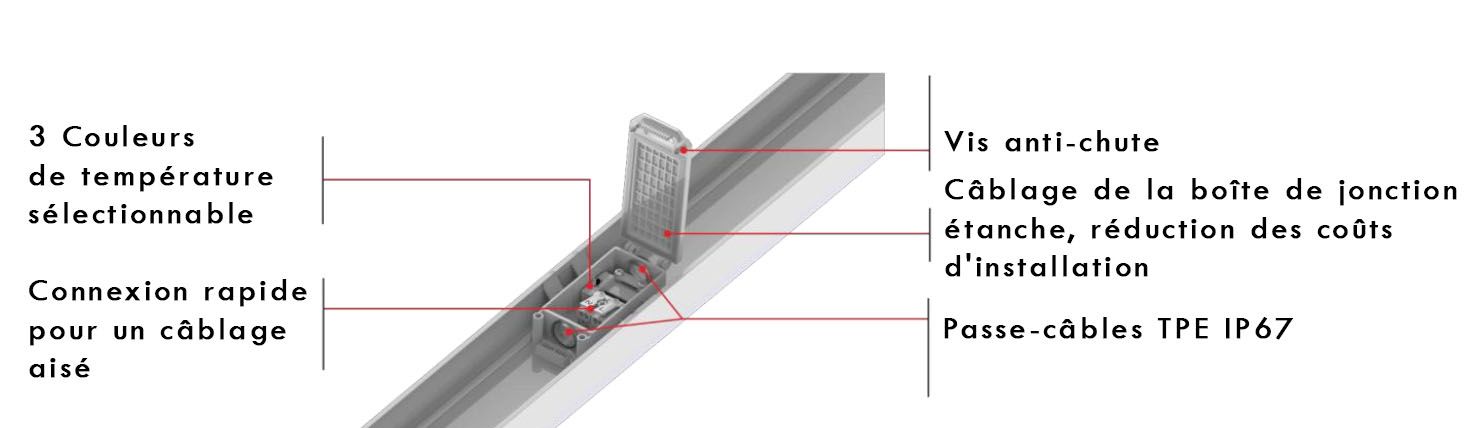

Linear industrial lampCONNECT Series3 in 1Adjustable color 3000k / 4000k / 6000k

120CM - 150CM

ADJUSTABLE temperature color!

1 Light, 3 temperature colors!

- Warm white 3000K

- Neutral white 4000K

- Cool white 6000k

Adjust the lighting color as you like directly with the adjustable button!

What are the advantages of polycarbonate materials for lighting?

Polycarbonate is a widely used material in the lighting industry due to its many benefits. Here are some of the key benefits of polycarbonate for lighting:

1 - High transparency: Polycarbonate offers excellent light transmission, meaning it allows light to pass through without much loss. This makes it an ideal material for lighting applications where brightness and clarity are important.

2 - Shock resistance: Polycarbonate is extremely impact resistant, making it very suitable for light fixtures and lampshades. It is able to withstand severe shocks and impacts without shattering, making it a safer and more durable material than traditional glass.

3 - Lightness: Polycarbonate is a lightweight material compared to other alternatives such as glass. This makes it easier to handle and install luminaires, reduces the overall weight of lighting products and allows for greater design flexibility.

4 - UV resistance: Polycarbonate is naturally resistant to ultraviolet (UV) rays. It will not fade or degrade under prolonged exposure to sunlight, making it an ideal choice for outdoor lighting applications.

5 - Design flexibility: Polycarbonate is a highly flexible material that can be molded and shaped into a variety of shapes and sizes. This allows lighting designers to create luminaires with complex and innovative designs, providing greater creative freedom.

6 - Good resistance to temperatures: Polycarbonate can withstand high temperatures without deforming or degrading. It maintains its mechanical properties over a wide temperature range, making it a suitable material for lighting environments where high temperatures may be present, such as recessed spotlights or halogen lamps.

7 - Economic: Compared to other materials such as glass or some specialty polymers, polycarbonate is generally more affordable, making it an economical option for commercial and residential lighting.

In summary, the advantages of polycarbonate for lighting include its high transparency, impact resistance, lightweight, UV resistance, design flexibility, temperature resistance, and affordability. These characteristics make it a popular choice for a wide range of lighting applications.

------------------------------------------------

CE & ROHS certification for lighting fixtures, what are the advantages?

CE (Conformité Européenne) certification and ROHS (Restriction of Hazardous Substances) certification are two important certifications for lighting fixtures. Here are the benefits associated with these certifications:

1 - CE Certification:

a - Compliance with European standards: The CE certification indicates that the luminaire meets the legal requirements and safety standards in force in the European Union. This guarantees that the product complies with the applicable European directives, which is mandatory in order to market and sell the luminaire on the European market.

b - Access to the European market:

CE certification is a legal requirement for many products in Europe. By obtaining this certification, luminaire manufacturers can access the vast European market without encountering regulatory barriers. This helps to expand the product's marketing reach and reach a larger number of potential customers.

c - Product safety assurance:

CE certification certifies that the luminaire has been assessed in terms of safety, health and environmental protection. It ensures that the product does not pose unacceptable risks to users and consumers. This strengthens customer confidence in the quality and safety of the luminaire.

2 - ROHS Certification:

a - Compliance with the restriction of hazardous substances:

ROHS certification certifies that the luminaire complies with the European ROHS directive, which aims to restrict the use of certain hazardous substances in electrical and electronic equipment. These substances include lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls (PBBs) and polybrominated diphenyl ethers (PBDEs). ROHS certification ensures that the luminaire complies with these restrictions, thereby reducing the environmental impact and health risks associated with these substances.

b - Environmental protection:

By meeting the requirements of ROHS certification, the luminaires help reduce the amount of harmful substances present in electronic waste. This helps preserve the environment by limiting pollution and encouraging more sustainable waste management practices.

c - Responsible branding:

ROHS certification demonstrates the manufacturer's commitment to sustainability and environmental protection. It helps communicate to customers and consumers that the luminaire has been manufactured using environmentally friendly materials, reinforcing the company's responsible and sustainable brand image.

In summary, CE and ROHS certifications for luminaires provide benefits such as compliance with European standards, access to the European market, product safety, compliance with hazardous substance restrictions, and environmental protection. These certifications are essential to meet legal requirements, ensure product quality and safety, and build customer confidence.

--------------------------------------------------------------------

IK08 protection index in lighting? More details!

The IK08 protection rating refers to the mechanical resistance of a luminaire or electrical equipment to external impacts. This means that the luminaire with an IK08 protection rating can withstand impacts of 5 joules of energy and is therefore considered relatively robust.

This can be an advantage in environments where there is a risk of shock or vibration, such as industrial areas, car parks, storage areas and public spaces. Luminaires with an IK08 rating can withstand impacts such as kicks, punches, vehicle impacts or falling objects without suffering significant damage.

However, it should be noted that the IK08 protection rating does not guarantee the quality of the lighting as such. It only refers to the mechanical resistance of the luminaire. It is therefore important to take into account other criteria such as luminous efficacy, colour temperature, light distribution and the service life of the light source to choose the right luminaire for each application.

--------------------------------------------------------------

IP65, what are the exact advantages?

Lighting with IP65 certification for an industrial lamp has several advantages:

1 - Dust protection:

IP65 certification guarantees total protection against dust. This means that the lamp is hermetically sealed and no dust particles can penetrate inside. This is particularly important in industrial environments where the presence of dust can compromise the performance of the lighting and lead to maintenance problems.

2 - Waterproofing:

The IP65 rating also indicates that the light is waterproof. It is able to withstand powerful jets of water from all directions, making it ideal for use in wet environments, such as production areas, warehouses or outdoor areas exposed to the elements.

3 - Increased durability:

Industrial lights with an IP65 certification are designed to be robust and durable. They are usually made from high-quality materials that can withstand harsh working conditions, including vibrations, shocks and temperature variations. As a result, they offer a longer lifespan and require less maintenance.

4 - Electrical safety:

The IP65 industrial light's waterproof rating also ensures electrical safety. It prevents water or moisture from entering the internal electrical components, reducing the risk of short circuits or any other potential electrical problems. This helps maintain a safe working environment for workers.

5 - Versatility:

Industrial lights with IP65 certification are versatile and can be used in a variety of applications. They are suitable for indoor and outdoor environments, and can be used in industries such as automotive, warehouse, construction, oil and gas, etc.

In summary, lighting with IP65 certification for industrial lamps offers total protection against dust, watertightness, increased durability, electrical safety and versatility for use in different industrial environments. This ensures reliable and efficient lighting, even in difficult working conditions.

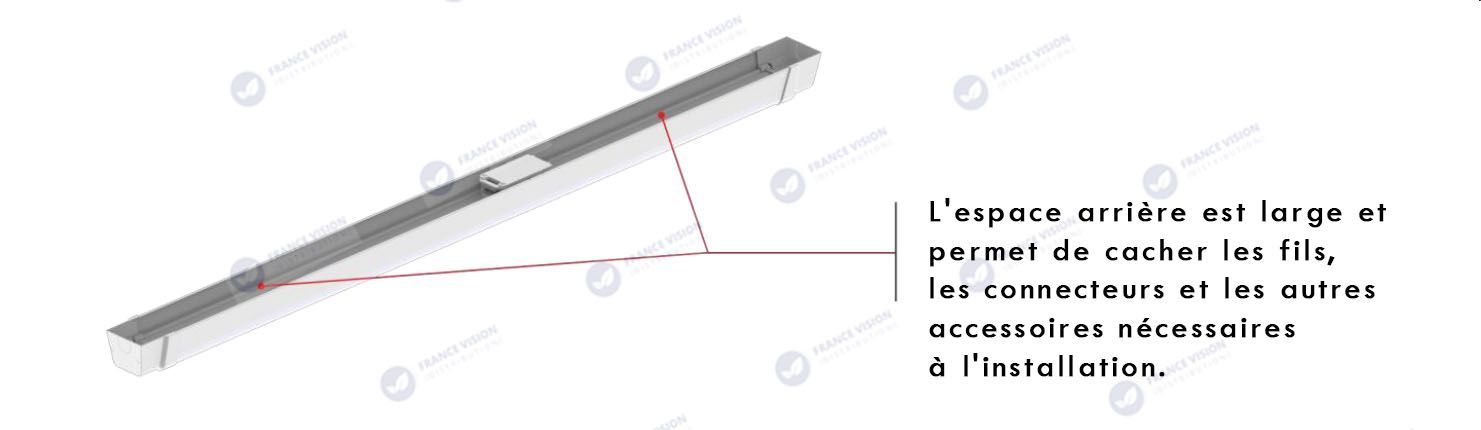

Connecting the strips in series

Strips are lighting devices commonly used in electrical installations. When it comes to connecting strips in series, it means that you want to connect several strips one after the other, so that the power supply flows through each of them.

------------------------------------------------

To connect strips in series, you will need a few items:

1 - Rulers:

These are the lighting units that you want to connect in series. They usually have connectors on each end to make it easier to hook up.

2 - Power cables:

You will need electrical cables to connect the strips together. Use suitable cables, such as two-core electrical cables with adequate insulation to avoid any electrical hazards.

Now, here are the general steps for connecting strips in series:

I - Make sure the power supply is turned off before you start. This ensures your safety during the connection process.

II - Take the first power cable and connect one end to the main power supply or a suitable power source.

III - At the other end of the first power cable, connect it to the input connector of the first strip. Make sure the connection is tight and secure.

IV - Take a second power cable and connect one end to the output connector of the first strip.

V - At the other end of the second power cable, connect it to the input connector of the second strip.

VI - Repeat steps 4 and 5 for each additional strip you wish to connect in series. Always connect the power cable to the output of the previous strip and to the input of the next strip.

VII - Once all the strips are connected in series, connect the last power cable to the output of the last strip and to the main power supply or power source.

VIII - Carefully check all connections to ensure that they are secure and that there is no contact between bare wires or conductors.

IX - Finally, turn on the power supply and check that all the strips light up correctly.

It is important to note that when connecting strips in series, the total voltage of the power supply is distributed among the strips. Therefore, it is important to follow the manufacturer's recommended voltage and power specifications for each strip to ensure safe and efficient operation.

Remember that handling electrical installations can be dangerous if you do not have the necessary knowledge. If you are not sure what you are doing, it is always best to call a qualified electrician to make the connections.

-------------------------------------------------

Advantages of Adjustable Temperature Colors in Lighting?

Adjustable temperature lighting, also known as "adjustable color temperature" or "adjustable lights," offers several benefits. Here are some of the main advantages of these types of lighting:

1 - Adaptability:

Adjustable temperature lighting allows you to adapt to different situations and needs. You can adjust the color of the light depending on the desired atmosphere or the activity being performed. For example, you can opt for a warm, soft light to create a relaxing atmosphere in a room or a cool, bright light for a task requiring increased concentration.

2 - Visual comfort:

The ability to adjust the color temperature of light can contribute to visual comfort. Some people prefer warmer, softer light, while others prefer cooler, brighter light. Temperature-adjustable lights provide the flexibility to meet individual preferences and improve visual comfort.

3 - Impact on mood:

The color of light can impact our mood and well-being. Temperature-controlled lighting offers the ability to create different atmospheres, which can positively influence our emotional state. For example, warm, subdued light can promote relaxation and rest, while cooler, energizing light can boost productivity and activity.

4 - Flexibility in decoration:

Adjustable temperature lighting offers greater flexibility in terms of decoration and interior design. You can play with different color temperatures to highlight certain decorative elements or create interesting contrasts in the space. This allows you to personalize the atmosphere and create attractive visual effects.

5 - Taking into account the circadian rhythm:

Circadian rhythm is our internal biological clock that regulates our sleep-wake cycle and other physiological functions. Lighting with adjustable temperature can be used to mimic natural variations in light throughout the day. For example, choosing warmer light in the evening can help you relax and prepare for sleep, while cooler light in the morning can help you stay alert and focused.

In summary, temperature-adjustable lighting offers increased versatility, improves visual comfort, influences mood, allows for greater flexibility in decorating, and can be used to accommodate our circadian rhythm. These benefits make it a popular choice for many residential, commercial, and institutional spaces.

60 Watts - 150CM